- Features

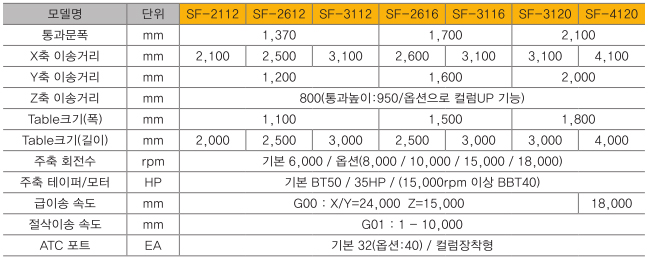

- Specifications

- Accessories

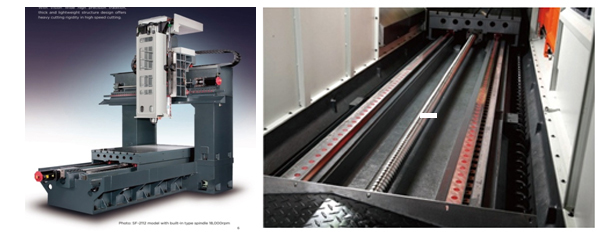

■ 크로스빔과 컬럼이 ㄷ자형의 일체형 구조로 견고하고 높은 정밀도를 유지함

■ 테이블 크기보다 넓은 베드구조로 중량물 적재시에도 안정적인 이송과 정밀도를 보장 함

■ 각축 이송은 독일제 Schneeberger 롤러 리니어이드를 장착하여 마찰을 죄소화하고 부드럽고 빠르며 초정밀한 이송이 실현됨

■ Y측 상부 롤러가이드는 크로스빔 상부에 설치하여 주축의 좌우이송을 보다 견고하게 잡아줌

■ 각축 볼스크류와 서보모터는 모두 직결식으로 체결하여 위치 반복 정밀도가 매우 뛰어나고 백래쉬 가 없음

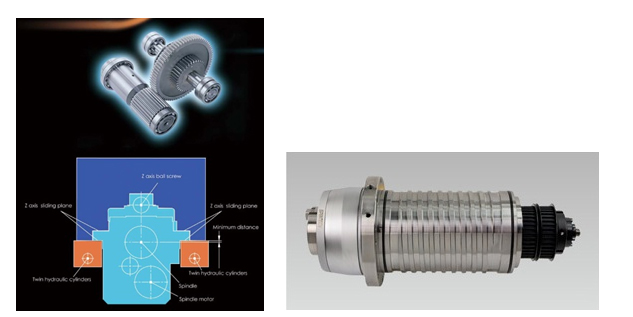

■ 주축기어는 일제 HAMADA 기어세트 일체를 장착하여 장기간 사용해도 열발생이 없고 내구성이 우수하며 기어소음을 최소화함.

■ 주축 슬라이드는 램타입으로 중절삭 가공시에도 진동이 없음

■ 기본 주축회전수 6,000rpm이며, 옵션으로 8,000 10,000 18,000 rpm 까지 선택할 수 있음

Standard Accessory & Function

- FANUC 0i MF controller

- 6,000rpm 2-step gear type spindle (Z axis box way)

- Spindle oil cooler

- Twin hydraulic cylinders with pressured air assistance balancing system

- Centralized auto lubrication system

- Independent lubrication oil collector

- Air blast through spindle

- Wash gun and pneumatic interface

- Cutting fluid cooling system

- 32 tools magazine with arm type ATC

- Sheet metal guard (without roof)

- Swiveling arm type operation panel

- Screw type chip conveyor on table side

- Caterpillar type chip conveyor

- Heat exchanger for electcrical cabinet

- Working lamp

- Operation cycle finish and alarm light

- Movable manual pulse generator

- Footswitch for tool clamping

- RJ 45 interface

- XYZ axis absolute pulse coder feedback

- XYZ axis travel hard limits protection

- Spindle cutting load software protection

- Remote monitoring software-standard (Not available for SIEMENS controller)

- Auto power off function

- Vision Wide FX-100 graphical user interface

- Foundation pads and bolts kits

- Adjustment tool and tool kits

- Technical manuals(operation, maintenance manual and circuit diagram)

Optional Accessory & Function

- 4,000rpm 2-step gear type spindle (Z axis box way)

- 8,000/ 10,000rpm belt-driven spindle

- 10,000(BT-50)/ 12,000(BT-40)rpm direct-driven spindle

- Z axis travel 1,020mm(box way spindle head, for AC head attachment)

- Z axis travel 1,000mm(linear way spindle head)

- 200/ 300/ 400/ 500mm higher column(SF-xx12 series only for 200mm higher column)

- Spindle ring cutting coolant device(for no head attachment)

- Coolant through spindle system 20/70 bar(Vertical spindle)

- Coolant through tool holder interface

- Coolant through tool holder 5/20 bar cutting fluid interface

- Oil skimmer

- Oil mist cooling device

- 40/60 tools magazine with arm type ATC

- Sheet metal guard with roof

- Chip auger on table side

- Chip cart

- Air conditioning for electrical cabinet

- XYZ axis linear scale feedback

- 3 axis independent manual pulse generator

- Sub working table

- Rotary table

- Interface reserved for fourth axis

- Spindle cutting load hardware protection

- Z axis retract function at power failure

- Anti-collision and process simulation software

- Remote monitoring software-professional (Not available for SIEMENS controller)

- Auto tool length measurement

- Auto workpiece measurement

- Transformer

- Auto warm up function

- Thermal compensation